A new era of automation in which humans and small-scale industrial robots work side-by-side on the same tasks has the potential to bring high-value production back to urban cores. New forms of urban metabolism in which materials are processed, used, and reused in creative ways by both humans and machines are establishing “Making” as a new urban common. This project explores the potential of using robots and computer vision to assemble a structure of irregular parts using a human operator in concert with adaptive assembly algorithms.

By developing software and hardware interfaces which incorporate machine vision, structural intelligence, and interactive visualizations, it is possible to create a collaborative construction process which balances the aesthetics and efficiency of natural materials with algorithmic intelligence, robotic dexterity, and human creativity. We have developed an intelligent system that operates with a fixed logic, but can be modified with material variation and strategic offerings, allowing us to use both the strengths of the robot (precision, stamina, and computational intelligence) and the strengths of the human operator (creativity, decision making, spontaneity) to achieve a shared goal. Further, by using found materials to assemble our structure, this project appeals to the light manufacturing industries already in place in Seoul, demonstrating the possibility of reusing scrap materials with low embodied energies and site-specific materiality in construction. By demonstrating principles of collaboration, reuse, and adaptability in the context of urban production, this project is a first step in understanding the potentials and limitations of collaborative robotics.

Roof, 2004-2005. Andy Goldsworthy

Digitally Integrated Adaptive Assembly

To overcome the lack of control in conventional construction sites, the vast majority of digitally fabricated structures rely on off-site prefabrication of building components in a controlled factory setting. This practice can reduce onsite labor costs, improve quality control, increase allowable complexity, and minimize material consumption when compared to similar methods of onsite construction. However, prefabrication can also be considered as a means of increasing the embodied energy associated with construction: materials are mass-produced in a centralized factory, and then shipped to a fabricator with the necessary computer numerically controlled (CNC) equipment and expertise in prefabrication. The fabricator post-processes this material into the required geometry, and again must transport the material to the site for assembly. Compared to traditional vernacular building methods which rely on locally available materials, this practice is incredibly inefficient in terms of material consumption and transportation energy. Moreover, the tight tolerances associated with digital design methods have served to bring intelligent decision making even farther from the place of construction, and thus also make it less tolerant of change. While most constructs must become fixed at some point in their materialization, pushing some amount of decisions back towards the construction site has the benefit of mitigating material and energy waste, while also working to make the completed structure appear less contrived. Architects often alter their fuzzy design concepts based on the limitations of their software and fabrication processes (i.e. changing curvature to meet ruled surface requirements); allowing design details to continue to take shape on the construction site (i.e. based on material limitations) should similarly be considered as a necessary aspect of design.

Robotic fabrication processes and machine intelligence have the potential to unite the previously incongruous concepts of regionally oriented adaptive assembly with digitally assisted design and manufacturing. Rather than working entirely top-down from custom components, recent work with industrial robotics has explored the potential of developing construction processes which begin with material understanding.

Gramazio and Kohler’s “Stratifications” project demonstrated one of the first examples of robotic construction using bricks with variable thicknesses.[1] GREYSHED’s “Bandsawn Bands” technique works to fabricate doubly curved surfaces from live-edged wood slabs by bounding the initial design concept within the constraints of naturally occurring, 3D scanned geometries.

Bandsawn Bands, 2013. GREYSHED

Similarly, the Woodchip Barn was constructed using digitally scanned tree fork sections culled from the surrounding forest and modified robotically.[2] By understanding the “material morphospace” of selected material subsets, computational methods can begin to prescribe methods for organizing, modifying, and aggregating found objects.[3] This capability will become increasingly available to architects with the continued development of onsite robotic systems,[4][5] improved sensing technologies, and machine learning.

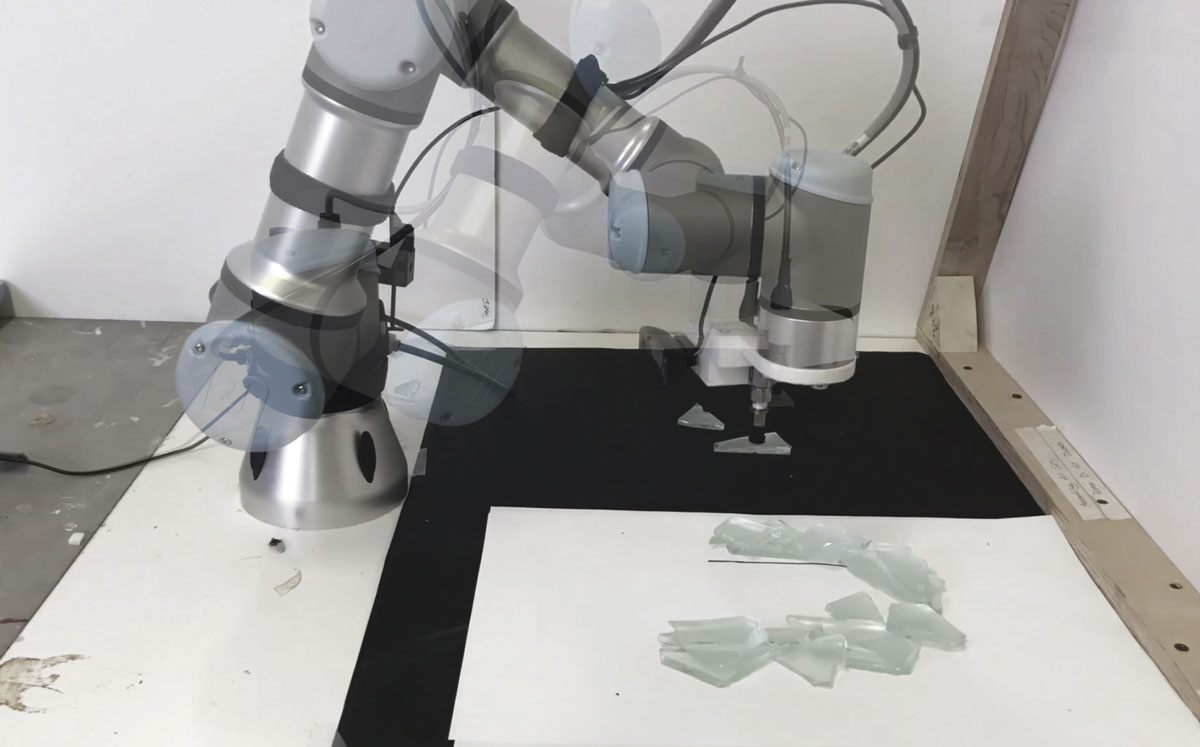

Adaptive Assembly is intended to convey the potential of integrating variable material properties with onsite robotics and collaborative/augmented design techniques. The project was developed with close connection to an ongoing research initiative at Columbia University’s Graduate School of Architecture, Planning and Preservation (GSAPP) which focuses on robotic assembly using rejected and repurposed materials. Student projects in the course “Assembling All Sorts” (led by Ryan Luke Johns) have worked to develop custom computer vision strategies and robotic workflows for creating constructs from materials ranging from lightbulbs to rubble, dried food and broken glass.