Among the many mutual relationships in the scales of timber dynamics articulated throughout this book, the thermal propensities of wood are perhaps the most immediately sensible to us. There are a number of physiological reciprocities between our bodies and massive timber buildings. Among them is the often colloquial, but quantifiable, association of “warmth” with wood. The thermal properties and behaviors specific to wood are not fully articulated in building science or in the wood industry, but they could impact how we come to characterize the thermodynamics, thermal potential, and ecologies of timber building.

While some thermal propensities of wood relate directly to our bodies, a better understanding of the thermal behavior and thermal potential of wood could more broadly impact the specific ways we use wood in massive building. This understanding extends not just to mass flow in regard to forestry sourcing and its associated carbon dynamics, but also to the operational fuel dynamics of buildings and (again) their associated carbon dynamics. So, seemingly small-scale movements of heat in wood and to wood can quickly cycle up to our largest scales, those of global carbon dynamics. In short, any cogent exergy matching design and carbon strategy for a massive timber building would necessarily put the possible quantities and qualities of wood’s thermal propensities to work at a range of scales and in a range of ways. Thus we need to learn how to couple daily fluxes of heat and air with the decades-long dynamics of forestry if we are to grasp the full potential of timber design.

Doing this requires basic knowledge of the structure and behavior of wood from a thermal perspective. This is the focus of this chapter. As an anisotropic material – that is, a nonhomogeneous material with varying characteristics in different axes of the material – wood exhibits several dynamics that are very relevant to how our bodies function thermally, to how buildings could accordingly be designed, and to how buildings could then function. In particular, a few thermal parameters can help us better understand how massive wood behaves, especially over time.

Architects too often are trained to assume that a steady-state condition of thermal conductivity is the basis of how heat and buildings relate. This grossly limits their understanding of heat transfer. In the context of massive wood building especially, heat transfer will generally be transient and periodic, that is, variable over time. Further, how materials might couple with air – both in terms of buoyancy-driven thermal strategies as well as interaction with the humidity in the bath of air of every building interior – attains unique significance in the context of massive timber building. Thus, more specific parameters should help characterize how a massive timber building will behave in thermal terms, as well as in terms of humidity, according to a range of performance factors. This chapter will discuss these properties and propensities of timber, and place them in their larger context, from the molecular to the territorial.

Thermal Diffusivity

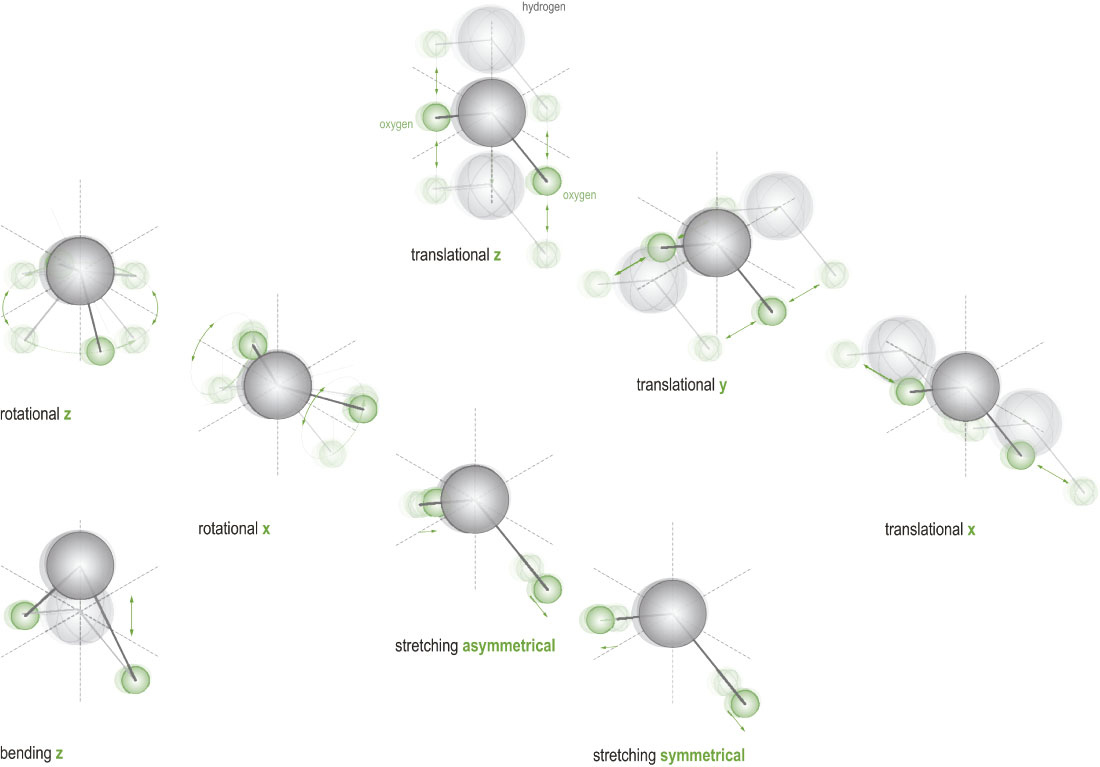

In more massive – as opposed to thinner and strictly planar – configurations of building materials, the volumetric and transient thermal properties of wood deserve particular attention. Thermal diffusivity, or the volumetric propagation of heat over time in a material, is important in this regard because it characterizes the relationship between conductivity, density, and specific heat. While often reduced to the rather vague concept of “thermal lag” in building science textbooks, the topic deserves more explication.

Thermal diffusivity is the conductivity of a material divided by the product of its density and specific heat capacity. In other words, diffusivity accounts for how much heat is stored per unit of material versus how much is conducted through the material. For massive materials, this phenomenon of storage versus transmission becomes quite important. While density and conductivity are perhaps more familiar to designers, specific heat capacity warrants greater attention.

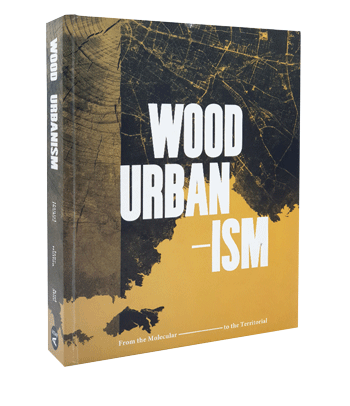

Specific heat capacity refers to the amount of heat necessary to alter the temperature of a mass unit of material. Edgar Marin provides a clear explanation of the internal dynamics of specific heat in this context: “the specific heat is the change in the internal energy per unit of temperature change. The more degrees of freedom the molecule has, the more energy it can store.”[1] This is a useful definition because it helps designers envision the actual behavior, at the molecular scale, that presupposes thermal lag – or, more specifically, thermal diffusivity. When heat is stored in a material, it is stored in the molecular movement of the material. The degree of freedom, as Marin observes, helps partly explain the range of specific heat capacity for solid and liquid materials of similar density. For example, water has more degrees of freedom (motion in three directions, as well as rotational and vibrational degrees of freedom) and thus has nearly five times greater heat capacity (4,182 J/kgoC) than concrete (880 J/kgoC), even if concrete is two and half times more dense (2,400 kg/m3 versus 1,000 kg/m3). The concrete has more molecules (density) but fewer degrees of movement. To state it another way, a higher specific heat value means that more energy is stored before there is a change in temperature. The heat applied to a pot of water first excites molecules in the water, so their multiple molecular movements increase with respect to their degrees of freedom and the resultant loosening of each molecule’s hydrogen bond. All that requires a significant amount of latent energy before a sensible change in temperature occurs. As you can imagine, the specific heat of wood will vary with its moisture content.

Water molecule degrees of freedom

So thermal diffusivity – again, thermal conductivity divided by the product of density and specific heat – introduces important phenomena to consider, given the mass of material involved in a timber building. For materials such as cross-laminated timber panels and for other mass timber construction strategies, thermal conductivity alone does not fully characterize the thermal behavior, or potential, of the system. Thus a common, but reductive, parameter like R-values has very limited efficacy when working out or imagining thermal strategies for mass timber buildings. Further, as an anisotropic material, wood will exhibit different conductivity values depending on if the transfer is primarily parallel or primarily perpendicular to the wood grain. Conductivity – based on Fourier’s equation – applies most simply to homogeneous and isotropic materials under steady-state conditions. So a more nuanced characterization of mass timber strategies is necessary. It would be thermodynamically, architecturally, and ecologically unfortunate to treat mass timber in ways, like the R-value or the U-value basis of most building energy codes, that do not account for its full thermal potential.

While a massive timber building might occasionally operate in periods where it exhibits steady-state behavior, thermal fluctuations not only are inevitable but can be put to work. Because the warming up and cooling off of massive materials is not instantaneous, time becomes a critical factor. This is why thermal diffusivity is important. It characterizes the amount of heat conducted through the material relative to the amount stored in the material over time. The thermal diffusivity of wood is lower than that of other construction materials like steel and concrete; it is closer to the diffusivity of rigid foam insulation. Yet it has a higher specific heat capacity than foams, if not as high as steel’s specific heat. As such, wood has a unique capacity to warm up more quickly with less heat and to store some of that heat while not conducting too much of it. So it is neither an insulator nor a traditional thermal mass. It exhibits very specific properties, and thus behaviors, that can be used as a central part of an exergy design for a massive timber building. While the transfer of heat in this context is more complex compared to thermal conductivity, so are the potential outcomes and designs. To this more nuanced end, another material property of wood that is very relevant to timber building is thermal effusivity.

Thermal Effusivity

In terms of occupation, human comfort is likewise not a steady-state condition but one that varies with time. The sun appears and disappears, internal heating loads rise and fall, and people assemble as group in a space and then disperse back to individual tasks. Again, while buildings may exhibit steady-state conditions for a certain period, people, air, and heat are variable. When people move from room to room or floor to floor (or in the case of different construction typologies, material to material), they sense temperature and transfer temperature in different ways. Far from a problem, this thermal variation over time can be an asset, even a form of thermal delight, or it may prove detrimental should it be expressed in thermal stress. Especially in the context of direct contacts of body and building, the role of thermal effusivity is essential to our sensation of thermal exchange in these variable thermal environments.

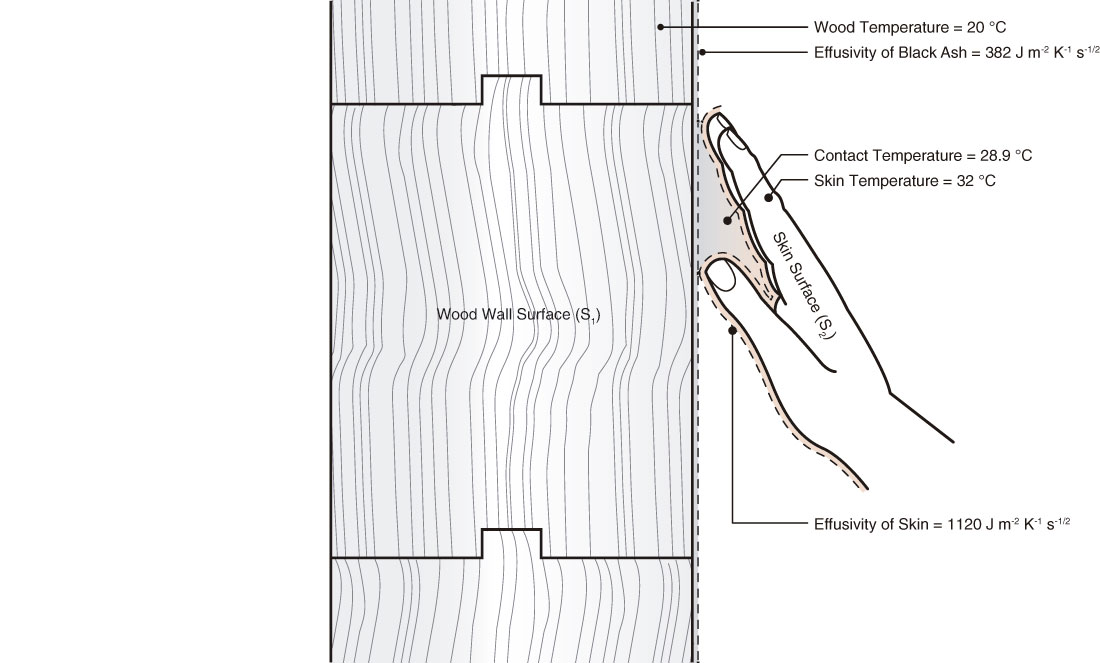

Thermal effusivity is a measure of the propensity of a material to exchange heat with its surroundings. It is most readily experienced when we touch a block of steel and then a block of wood. Even if the blocks are at the same temperature, the steel block will feel cool while the wood block will feel warm. The difference in the experienced, tactile, and felt temperature compared to the measured temperature of the material is explained by thermal effusivity.[2] Wood has a lower thermal effusivity than our skin, while the steel’s thermal effusivity is considerably higher than our hand.

While overtly subjective in sensation, the thermal effusivity of building materials can be quantified.[3] The thermal effusivity relationship between the palm of the hand (1.263 kJ/m2s1/2 K) and larch wood (0.403), compared with that between the hand and steel (12.53), explicitly articulates what is intuitively known about the relative “warmth” of materials. Likewise, the thermal engagement of the sole of the bare foot (1.012) with various flooring materials – granite (3.54) versus maple (0.57) – similarly affirms what the body already knows. Thermoreceptors in our skin sense less heat transfer from body to wood than from body to steel. Your body does not measure heat transfer itself, but senses the relative rate of heat transfer. So modifying the sensation of heat transfer through thermal effusivity specification will impact perceived thermal comfort.

In this way, the qualitative “warmth” of wood could quantitatively enter the thermal design of massive timber buildings. The sensation of wood’s perceived warmth is an important aspect of wood building around the world. From sauna culture, to the Korean ondol’s underfloor heating, to Alpine huts, the role of thermal effusivity is one of the most familiar but unarticulated factors of wood’s thermal performance relative to our comfort. Given its importance, it should consciously enter our models of thermal design, analysis, and calculation. If designed with thermal effusivity in mind, a wood interior could be effectively colder than a room of other materials. This would lower the overall exergy requirements of thermal comfort in hot climes, impacting fuel demands and carbon emissions.

Thermal effusivity

Hygrothermal Behavior

If wood can behave as a modulator of thermal variation, its cellular solid material architecture also exhibits capacities to modulate moisture and humidity.[4] Wood has the capacity to accumulate and release moisture to its surrounding environment, much as it does with heat, as well as to “pump” moisture through its vascular structure through pressure differences. Rooms with a wood surface area exposed to the interior will have a capacity buffer against moisture variations, alongside wood’s thermal buffering.[5] Ideally, this hygrothermal propensity, again somewhat unique to wood, would be considered as part of the exergy design of a building, possibly reducing or eliminating the need for a humidity control system in the context of some building types and some climates.

In this context, it should also be noted that the thermal properties and performance of a wood assembly are quite dependent on the water content of the wood. The amount of water present will affect the conductivity, specific heat capacity, diffusivity and effusivity of the wood. In other words, it is important to think about wood in thermal terms that include both sensible heat and latent heat potentials. Again, the nuances and complexity increase the more specific we get about the work that wood can do in thermal terms, but so do the architectural and ecological outcomes as positive impacts multiply with this greater specificity.

Thermal Strategies in the Energy, Environments & Design Lab

This chapter helps, in a very preliminary way, to frame some of the latent thermal and hygrothermal propensities of timber building. The relationship of conductivity to specific heat, density, and effusivity can illuminate the thermal possibilities of wood. As with the other chapters, here we combine design, research projects, and built projects to help illustrate and explicate many of these thermal opportunities for massive timber building. First, Sal Craig will expand in detail on a couple of novel thermal strategies that can be used in the context of massive wood building. His work on “breathing walls” and the thermal resonance of buildings reflects some of the most engaging and promising thermal design in architecture.

Some of the students with projects in this book have begun to think about the implications of Craig’s work. As Craig notes, these thermal strategies are not tied to any single material. But as the student projects indicate, the specific properties, and technics, of massive wood building in particular can suit these strategies well. These projects speculate on how some of these novel thermal strategies might be incorporated into specific massive wood building techniques. For instance, the cross-laminated timber panel assembly process lends itself to “choked convection cavity” designs. With this technique, the composite thermal performance of the panel can be increased several times over by employing the right thickness of distributed cavities. Further, the removal of some structurally redundant material to create the cavities reduces the weight of the panel and its overall woodshed.

In another example, the technics and mass of non-adhered, doweled panels – such as panels made with the Brettstapel technique – lend themselves to Craig’s “breathing wall” strategy. While denser materials are initially the more intuitive choice for this strategy, the relative thickness of a Brettstapel panel, as well as the inevitability that a multitude of holes will be drilled in the panel, suit the basic parameters of a “breathing wall” well. In all cases, though, the collective aim of this chapter is to present some of the inherent thermal opportunities that are not yet well articulated in the context of massive timber building.

A couple of built projects offer insight on some atypical construction and thermal considerations of wood buildings. The Atelier N11 project by Sascha Schar in Zweisimmen, Switzerland, is compelling to consider in this regard. Tom Sherman describes how this building uses its mass in particular ways as a central part of its thermal strategy. This building, perhaps more than any other, experiments with some of the specific thermal properties and behavior of wood.

Thermal + Other Factors

While this chapter focuses on the thermal interactions of bodies and timber building, how this subject connects to the other chapters is, of course, worth considering. It is perhaps daunting, or at least difficult, for us to maintain a coherent focus on the molecular dynamics of heat propagation in wood and at the same time think about the propagation of various trees species in a forest management plan, but this book suggests that there is much to be gained by meeting this challenge.

For instance, the thermal capacities and behaviors of timber building can impact the carbon cycles of building in multiple ways. The substitution of wood for fossil fuel and carbon-intensive building materials such as concrete and steel is one major impact. Another is the substitution of biomass for fossil fuel and carbon-intensive fuels for heating and cooling. The use of timber building material by-products, such as the biomass pellet fuel produced from building material production “waste,” can impact the total carbon dynamic of a building. Further, from an exergy perspective, we can keep people comfortable with lower air temperatures through cunning thermal effusivity designs and “breathing wall” strategies in massive timber building. When taken together, the novel thermal strategies, renewable fuel sources, and less carbon-intensive building materials converge in a timber building in a unique way, and the total ecology of the building becomes more coherent and powerful. If anything, this convergence and coherency begs other further questions about how these building-related products are connected to adjacent forestry practices, labor, and urbanism. The possibilities and potentials of these nested systems, and how they could relate through design, is at the core of the motivation for this book.

Once these multivariate, multi-scalar, and multidisciplinary concerns become a habit of mind for designers, an ecologically valid mode of building and urbanization may potentially emerge. In this regard, the thermal consideration of timber is but one entry point into the complex, but knowable and practicable, interactions of timber, bodies, forests, urbanization, and civilization. Small-scale molecular movements and behaviors are directly connected to these much larger scales of material movements and solar flux. When the entirety is properly grasped, it becomes impossible to think about wood without thinking about the carbon dioxide and light absorbed in a leaf that is then “printed” as a carbohydrate in the trunk of a tree; how that trunk becomes a timber, comprised of many molecules vibrating from the sun’s insolation to warm an adjacent body; and how those timbers are but one of many in a building, each the product of a forestry practice that will either amplify or constrict life in the forest and its adjacent societies.