This chapter discusses a series of projects that revolve around the Pleat, a fashion and textile technique I have explored to develop an understanding around where fashion, textile design can be used to develop architecture, and how the differences in these approaches can be used to develop an architecture that considers material, structure, skin and form at the same time and not a separate processes. Through the design and fabrication explorations of the Pleat, I have applied the lessons learned from the previous collaborations with fashion and textile design, discarded peripheral directions, and established a way of operating for future projects. The projects discussed in this chapter include the Pleat Pod, Pleat Pavilion and Pleatent. These projects have used the process of developing smaller tests or croquis developed through the collaborations to inform the larger architectural propositions of the Pleat projects. The images in this section document the processes taken, problems encountered and resolutions to communicate the benefits and possibilities of working in the space between fashion, textile design and architecture.

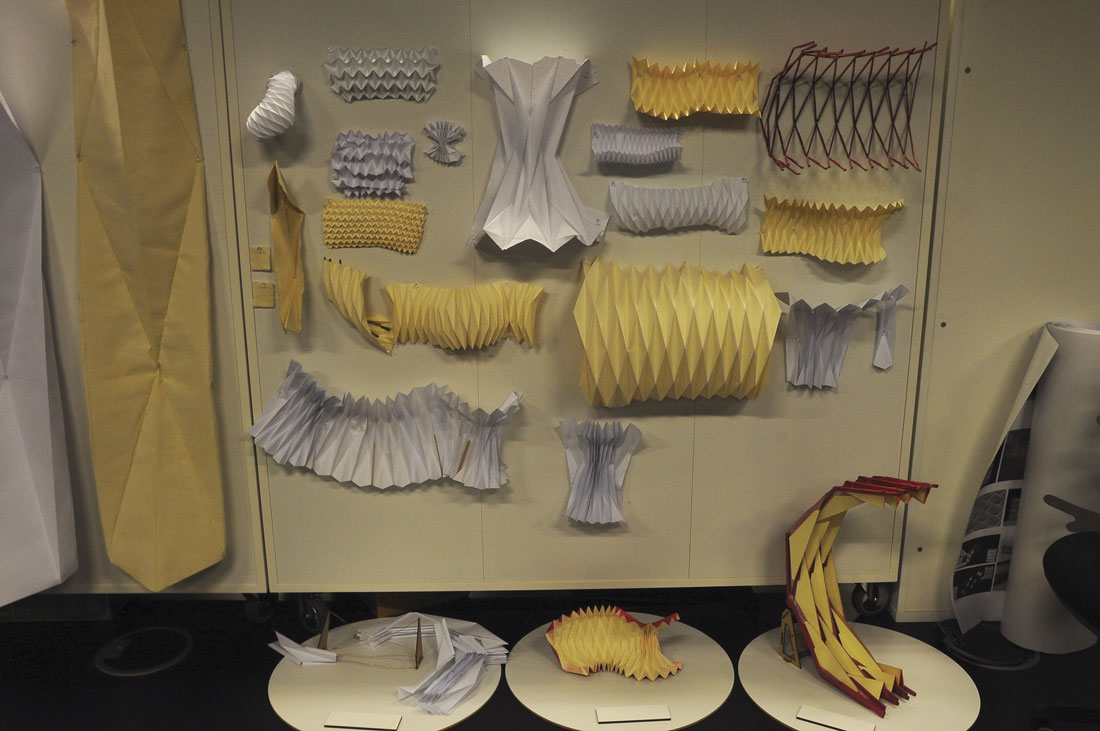

Peat tests during development of the PlestPod © Leanne Zilka

Pleat vs. Fold

The differences between the pleat and the fold are important to distinguish, as it is the investigation of these differences that illustrate how fashion and textile design consider pattern, form and structure together and how architecture considers them separately. I compare these two terms because I see Fold as a common and familiar term within architecture and Pleat as its equivalent in fashion and textile design. By looking at the way each discipline considers these techniques, new territory is revealed that lies between the disciplines.

A pleat is a type of fold formed by doubling fabric back upon itself and securing it in place and is a composition of a set of repeated folds. The pleat is commonly used in clothing and upholstery to gather a wide piece of fabric around a circumference. Pleats are categorized as pressed, that is, ironed or otherwise heat-set into a sharp crease; or un-pressed, falling in soft rounded folds. [1] I understand a pleat to be a combination of pattern and form that involves many folds.

A fold is the act of folding a material back onto itself to create structural stability and/or visual effect from a sheet of material. Unlike the pleat, where the network of folds is fixed in some places and loose in others, folding is a singular technique that is repeated to create pattern and is only effective with sheet materials that have inherent stiffness, such as paper. While the fold can be used for numerous purposes, in architecture it is typically used to create patterns for aesthetic purposes. A fold in architecture is predictable and controllable, where the act of folding works to strengthen a material and disguise material sizes, giving the appearance of a continuous skin, it does not communicate a material condition, for example how flexible a piece of steel or aluminium is because once the steel or aluminium goes through the folding process it is fixed to a supporting structure and does not move. The fold also does not reveal the material (i.e. if it is aluminium or steel), the thickness or weight of the material, nor how far the material can be pushed before it fails. The pleat, on the other hand, refers to a fabric that gathers in strategic areas on the body, it is not a continuous treatment but is used at points around the body, for example at the waist of a skirt, allowing the fabric to fall, responding to the hips and then legs. The pleat is dependent on the weight, flexibility, and thickness of the material used, the ‘springing’ points of the pleat, and the form it is attached to.

The functional difference between the pleat and the fold helps to explain the way architecture and fashion deal with form. By working between fashion, textile design and architecture, form in architecture is used to enclose program, address context, express a materiality, and deal with climate and site. There is typically an external reason driving the formation of the material. The scale used when developing architecture means there is often a disconnect between the generation of the form (done at a variety of scales with different materials) and its materialisation. That is, the material is considered after the building envelope has been developed, even if it is considered during the design process it is rendered submissive to the formal testing. Fashion and textile design, however, deal directly with a fixed form – the body, which can be described a composite of complex forms (head to shoulders, leg to hip etc.). Fashion and textile design use techniques such as pleating to alter the shape or form of the body as they the body itself cannot be altered.

The practice of fashion and textile design has developed techniques over time to translate ideas or concepts from the body into garments. Working with practitioners in these disciplines reveals the ways they work and the tools (both physical and conceptual) used. These techniques and approaches give an alternative appreciation of a material condition that can be used to develop architecture.

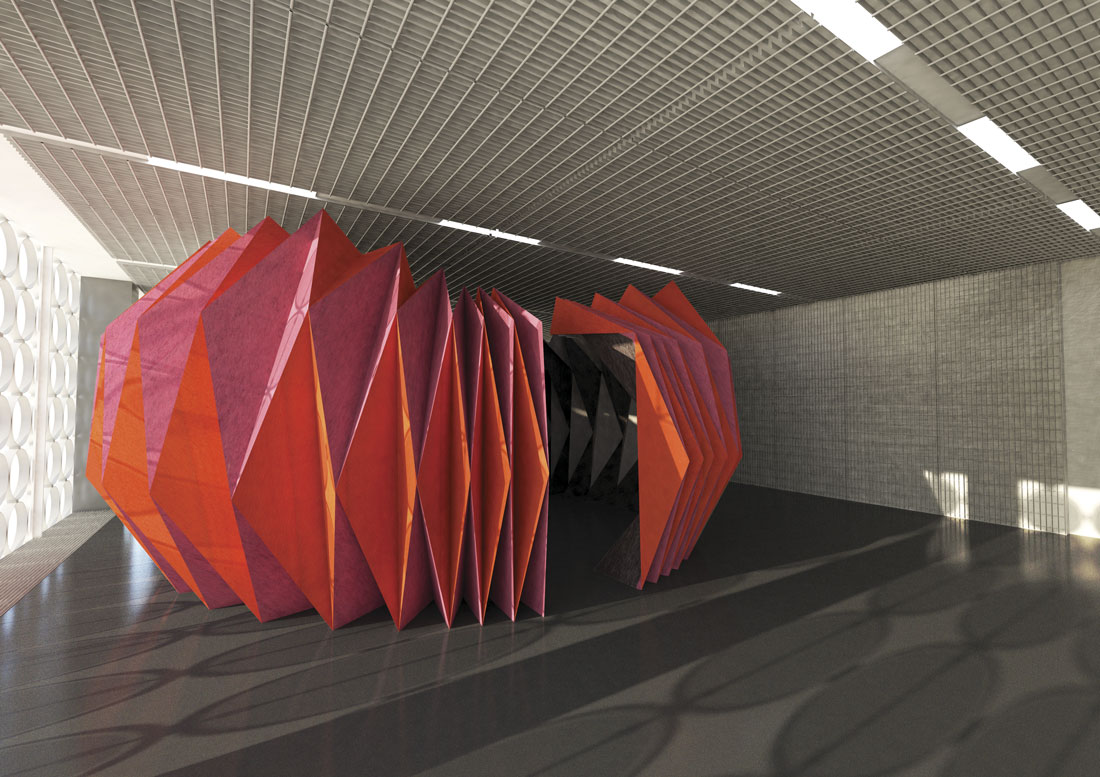

Final rendered image of the PleatPod prior to fabrication © Leanne Zilka & Bruce Oakley

PleatPod

The PleatPod works with pleating to create pattern and structure. When working with fabric, there is a need to work through a solution that takes on the structural simultaneously as the concept develops.

When developing architecture there are stages of development and while concepts might be conceived with a material logic, working with the Floppy range of materials requires thought around the specific material first as these sets of materials have no strength to begin with. There is a fine balance between ‘freezing’ materials, (rendering them so they no longer possess the qualities of the material, only the appearance) and providing support to simply assist materials which still allow its qualities to remain. Working with the Floppy is the exploration of where the material logic sits and where it becomes contrived. It involves the development of a logic that finds navigates a clear path around when a material character is revealed and when it is obscured by the structure, enclosure or form.

Initially the PleatPod was called the KnitPav (knitted pavilion) and was envisioned as a structured curtain that would hang from a track embedded in the ceiling. Users would be able to wrap the curtain around an interior meeting space when needed and then pack it away, and this flexibility would allow the curtain to take on many configurations. This was a direct response to the brief for a solution to open plan offices that require privacy for meetings. Where the Glow project had tensioned tubes, the KnitPav worked with gravity to create pleats.

The structure of the KnitPav was to have stiffening inserts in the curtain to give form and folds as it hangs from a ceiling track in the same way a garment hangs off a body. It was to be constructed from an acoustic felt and the inserts were to add to the absorptive qualities of the material. The embedded frame was inspired by a corset. A structure independent of the garment used to constrain the body and articulate a desired body shape. Corsets are constructed from many fine elements to reduce overall weight, allowing for many fixing points for the garment to connect to. These intricate structures work to create an illusion around the form of the body. [2]

Exploring how fabric can have an embedded structure that also gives it form, began with paper folding. This exploration gives an understanding of what a fold can do to a Floppy piece of paper and how the act of folding can create more rigidity in the paper. Pleating was referenced here as it was a way to expand the potential of the fold to create form.

Working from the scale of paper to the scale of architecture throws up a range of questions around how to develop form using the technique of pleating without a body for support. Or How can we translate a material logic between the different scales. Or how do you increase the scale of the pattern so that it is not only decorative? Or which aspect of the initial design concept is robust enough to cope with the jump in scale? Or how do you ensure form follows these scale increases?

Using folded paper as a way to investigate patterns is useful as it is clear when the pattern strengthened the paper or when it makes the paper weaker. These explorations also tested aesthetics, spatial potential and how the folds would stop, either at ground or at ceiling. When scaling up, material limitations were considered, not only the limitations of the size of the fabric or sheet material but also its thickness. As the paper samples increased in size so too did the thickness of the material. This was necessary because material and technique are linked, i.e.: if the paper is too thick the pattern becomes obsolete as the inherent strength of the paper takes over and vice versa, if the paper is too thin the folding remains only decorative.

The Pleat experiments show, that by understanding the effect of pattern on material, a structural language can develop that integrates stability with pattern and pattern can express a load path. The column and cantilever were basic structural principles used to assess the likelihood that a pattern would create rigidity in the paper. Initially this stability was through the addition of structure such as sticks to act as columns or doubling up parts of the paper to add strength, so the structure could cantilever. These extra bits of structure were then absorbed into the pattern through longer folds, double folds or shifts in pattern.

Once the logic of the fold as structure became clear, the scale of the tests increased. The half scale model was used to test stability and the operability of the panelised pleat which was able to express form and allowed for feet to be incorporated. The structure slowly lost its reliance on being hung from the ceiling and was able to sit on the ground.

Exploded Axonometric showing the curtain track and pleated fabric of the KnitPav

Plan of KnitPav

Knitpav to Pleatpod

After the work done on the initial KnitPav, the competition required more refinement of the concept around buildability. The name shifted from KnitPav to PleatPod as the pleat became the central point of investigation that allowed for structural support and departed from a solution that would be hung from a track. Working with a pleat pattern made the PleatPod look like a garment that would wrap around a space (an invisible body).

The challenge of how to create a fabric that did not simply hang but held its own weight relied on an idea of a frame or corset where fine crisscrossed timber would be hinged at each frame intersection. The fine-ness of the frame would hide the structure between two layers of fabric giving the illusion of a curtain. By focusing on the structure of the ‘curtain’, the ceiling track became obsolete as there was a conflict between the sturdiness of the frame with the hanging of the curtain – two very different concepts.

Scale, pattern, structure the form of the PleatPod was constantly adjusted and assessed visually to absorb changes. Even the most incremental shift impacted on the form. Some of the pleated trials gave too much enclosure and others not enough, some options looked less like a pleated enclosure and more like a tent, hitting the ground heavily. The digital model was used to visualise the form and the physical trials tested material conditions, structural stability and pattern.

The final form was decided upon when I saw enough variety in the pattern that made the PleatPod look as if it was fixed in motion or seemed to be in mid-fold. While the reality of creating a fully flexible form was becoming increasingly difficult, working with the idea of a flexible enclosure allowed for the form to shift and change easily. Operability became a technique used to develop the form. The geometry of the final form alluded to a folded architecture, bringing back the lessons from fashion, where the form of the body dictated the behavior of the pleat. The accentuation of the body occurs by expanding a pleat pattern. The ‘body’ in the case of the PleatPod was invisible but was still driving the manipulation of the pleats.

To ensure stability, the final form was given to structural engineers [3] for modeling. 3d prints were used to test stability of the components and the parts prior to fabrication. Even at the small scale of the 3d prints, over 50% of the elements were unable to stand independently. A structural engineer studied the form, and material and agreed that the PleatPod would stand once the whole structure was complete. Highlighting the elements that were not able to stand independently and the ones that were stable. The stable panels gave strength to the unstable panels in the same way a cantilever works. The compressed pleats acted as columns and beams supporting the more open pleats. In addition to this the circular form of the plan of the PleatPod allowed for the additional support from the geometry.

Materially, there was a shift away from only using acoustic board to creating a composite material of MDF, acoustic board and acoustic felt. The acoustic board alone, failed as it sagged over time and its rigidity could not be guaranteed. A more stable board would need to be incorporated to withstand impact from users as well as sag from the acoustic material.

A composite panel that had routed out MDF sheet (to lighten the panels) sandwiched to an acoustic sheet and then dressed or covered with fabric, was decided upon as it gave the illusion of a pure fabric structure. At this stage there was confidence in the geometry and the logic of the structure to progress without full scale tests. The flexible components were assigned to the entry only, again providing an illusion that the whole structure could be compressed and expanded.

Rendered image of KnitPav in open position

Rendered image of KnitPav in closed position

Hinge

Working with the idea of an operable curtain drove the initial design of the KnitPav then the PleatPod. The folds in the early paper models acted as hinges, and this concept remained during the development. Jenny Underwood (textile designer) assisted in developing the connection between paper, fabric and then MDF panels so that the PleatPod would look like a seamless object, folding and unfolding. Jenny’s understanding around embedding hinges seen in knitted garments, (the way a sock turns from ankle to foot through a change in the knitted pattern at the junction) was used and resulted in a range of options to create a discrete operability. This was the logic applied to connections between elements in the PleatPod to develop a seamless architecture that would hide the composite of materials and connections used and express the form with minimal interference, in the same way that sewing is hidden in garments.

The initial hinging experiments worked with cardboard and masking tape to understand the stresses on the folds when numerous pieces are joined together. As the scale increased there was instability caused by twisting. The material scale needed to be in proportion to the scale of the final PleatPod otherwise there would be discrepancy in the behaviours of hinge vs material.

Once the form and hinge system seemed resolved enough we then increased the scale and tested the system with acoustic board and felt. As the acoustic board was made up of 2 layers there was thought around slicing through one layer of the board and using the other layer as the flexible hinge. Part of the PleatPod were made a full scale to test the hinge further.

The trials of the flexible hinge consistently failed, and the decision was made to abandon the flexible direction, as it became apparent that it was impossible to reconcile the form with the need for flexibility. The intricate folds and illusion of the structure being a continuous folded piece of material became more important than pursuing operability.

To make the PleatPod operable the form would need to be less curved to balance the motion of moving the pleats. The exploration into flexibility while useful in developing form, ultimately conflicted with the form.

The final PleatPod was constructed of, what I called columns that were each made up of eight triangles mitered together. The centre of gravity of the columns changed depending on their shape so the more open or vertical the columns the lower the center of gravity and the less stable the column. When the connections were tested for flexibility the top of some of the columns began to swing and became too difficult and heavy to fold.

The iterations have always been made as flexible tests, as this allows for an understanding of where the impact of even the slightest shift in the form occurs. When the fold expanded or contracted, the it was easy to see where the form could be self-supporting or required more material. Each movement informing the whole. By using the flexible model there has been an efficient way of viewing the consequences of small shifts on form, structure and skin.