The world of advanced materials is a highly competitive arena, but there is one company that could never fail. (…) That company is Life, and its materials the most advanced on the planet. — Phillip Ball [1]

Re-programming Function

In the late 1800s, the architect Luis Sullivan aimed to reinvent ornament, moving away from artifice and toward forms true to matter, in defense of a re-integration of form and function [2], [3]. Such integration is inseparable in nature’s structures but has long been dissociated in design and engineering. This is because we are still heirs to the Industrial Revolution’s mottos of standardization, homogenization, modularity, redundancy and repeatability [4]. The emphasis on design and fabrication according to single-function parts and assemblies stands in opposition to the continuous growth and multifunctional property adaptation found in nature [5]–[7]. Biological constructs, such as seeds, branches, and trees, adapt to external stimuli by growth-induced material property variation, resulting in forms that are indissociable from their materiality [8]. The forms in forests are a result of materials and shapes that must attune to combined environmental requirements spanning optical (translucent to opaque), mechanical (flexible to tough), or structural (porous to dense) properties. In contrast, the conventional processes with which we design consumer products are lacking the tools to better understand the properties of matter, as well as a robust integration of formal decisions with the possible functions of the materials themselves [9], [10]. This limits designers’ imaginations when it comes to devising material-based forms or inventing new functions to augment everyday objects.

Today, there is a new way to re-program function, which design needs to catch up to.

Learning from the functionalization of biomaterials in biomedical disciplines, we can transform the properties of natural matter and propose new unforeseen function within forms. This can permit design processes that are not only material-aware, or driven by material behavior, but which also embody infinite capabilities towards the future of programmable matter, beyond Sullivan’s functionalist dreams and today’s synthetic smart materials research. Moreover, we can do it with green chemistry and sustainable outcomes. Importantly, strategies to formalize multiple surprising properties within the same object could present us with new solutions, such as, for instance, beams with internal structures informed by load-responsive chemical sensing, windows with optically graded nanogeometry surfacing informed by sunlight incidence and the required reflectivity, furniture with physically aligned polymer chains in patterns informed by shape stress lines, and garments with soft-to-hard fiber networks informed by comfort needs and impact distribution.

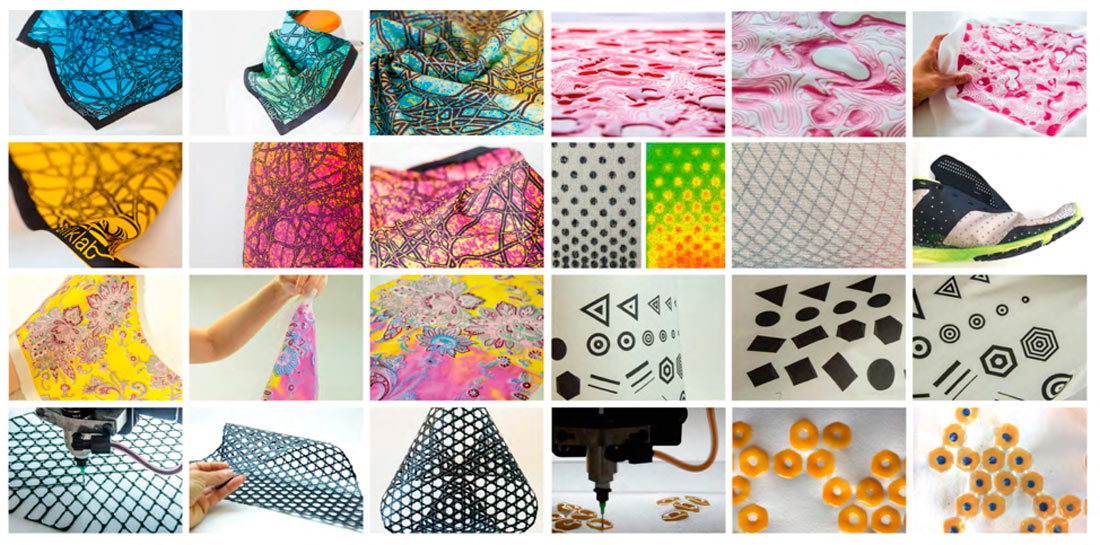

Augmented function products that heat up with light, change opacity in response to touch, show color with chemistry, or curl with steam, are developed by architect Laia Mogas and engineer Giusy Matzeu at the Living Materials Silklab (http://ase.tufts.edu/biomedical/unolab/home.html).

Borrowing from Pharma and Medical

In order to achieve the aforementioned designs, it is key to research biomaterial systems that can be harnessed. For the past decade, designers and architects have looked at bio-based materials with the potential to substitute, functionally augment, and sustainably enhance everyday objects such as bricks, fabric, furniture or building systems. This is because natural matter, and specifically structural proteins, polymers, and polysaccharides, provide for a vast renewable resource of versatile materials that enable a variety of novel mechanical forms and chemical functions [7], [11], [12]. Cellulose, which provides structure for plants, and chitin, which supports the exoskeleton of insects and crustaceans [7], [13], have elastic moduli and tensile strength similar to those of engineering ceramics and metal alloys [14]. Structural proteins such as silk fibroin have remarkable mechanical and optical properties and represent the strongest natural fibers known to man, providing an alternative to materials such as Kevlar or steel [11]. Derivates from cellulose, chitin, or silk, could replace existing synthetic fuel-based polymers, provide new property combinations for relevant applications, and play a key role in future manufacturing implementations [13], [14].

In particular, biomaterials used in pharmaceutical and medical applications present a mechanically viable and yet environmentally friendly fully degradable alternative to man-made plastics, which are challenging to reuse or degrade [15]. Only about 9% of the plastic waste generated in the US is recyclable, while 27% of glass, 34% of metal, and 65% of cardboard are routinely recycled [15]. In the construction industry, synthetic plastics derived from petrochemicals are vastly used and make up most of the pollutant non-recyclable waste [15]. While bio-materials could provide an alternative to fuel-based plastic, their use for product, architectural, and engineering applications is still not widespread [16]. This low use rate exists in spite of the fact that natural materials display exceptional mechanical properties [14], [16], [17].

Recent research in tissue engineering proves that biodegradable scaffolds from natural gums, proteins, and biopolymers show significantly improved mechanical and biological properties [18]. They can be a manufacturing medium for three-dimensional (3D) objects, thereby offering a new pathway for the large-scale production of fully compostable engineered components with complex forms. Recent developments have deployed conventional manufacturing methods such as injection casting to produce functional 3D industrial products, such as fully compostable cups and egg-storing containers [16], [17], [19]. The non-toxicity, water solubility, capacity for swelling, and chemical versatility of a growing catalogue of biomaterial composites allows for the development of advanced functionalized materials that can be used on multiple scales, including drug delivery, tissue scaffolding, consumer products or large-scale architectural parts [16], [20]–[22].

“Lachesis: Drawing the Fabric of Life” (https://vimeo.com/304908228) are interactive tapestries able to respond to their environment by changing color. The display at the Barcelona Design Museum allowed visitors to transform the fabrics by exposing them to chemical compositions emulating daily life, such as harsh chemicals on our skin, hydration levels in our sweat, or acidity in rain and oceans. Fundamental science behind the Lachesis project presents the opportunity to newly design or convert surfaces of any kind into interactive devices with distributed sensing abilities. Developed by architect Laia Mogas and engineer Giusy Matzeu at the Living Materials Silklab, led by Dr. Fiorenzo Omenetto.

From Biomimicry to Bio-based Fabrication

Design and fabrication with natural materials started with the rise of human civilization in the vernacular construction of early settlements [23]. These were made of leather, adobe, and wood [23], which helped overcome crucial architectural constraints, including the mechanical adaptation to environmental parameters of varying humidity and loads, breathability and impermeability, thermal inertia, or graded and tunable elasticity [24]. However, surprisingly, most recent advances in materials science for architecture and engineering have focused on the synthesis of artificial smart materials, and not much progress has been made in enhancing the properties of existing organic materials and solutions [1]. Biomaterials such as silk, cellulose, or chitin present an opportunity to incorporate new performative and sustainable material building blocks into architecture and design. They are readily available and do not require complicated chemistry processing to turn them into useful forms and functions. They also possess, by evolutionary refinement, many of the properties that man-made smart materials seek [1], [25].

The Roman engineer Vitruvius famously stated that structures must exhibit the qualities of being “solid”, “useful”, and “beautiful” [26]. This was later restated by the Modernist architect Louis Sullivan as the need for form to follow function [2]. Sullivan’s aim was to invent a new vocabulary of forms true to matter, moving ornament away from applied artifice and toward structurally-derived monumentality Some of the reasons for this phenomenon are, again, the pressure of mass production during the Industrial Revolution and the spread of form-only-driven digital design environments within design disciplines. Today, not only can we design form following function; we can also design new functions within forms through bio-technological processes that open up aesthetics through material augmentation. Specifically, biomaterials are great candidates to embed new performance due to their molecular makeup that allows for chemical functionalization – i.e., the introduction of new functional groups within a molecule to provide new material behavior such as adhesion, stabilization, solubility, environmental sensing, etc. [27]. This process of functionalization makes biological materials great candidates to serve as models and building blocks for the advanced materials of the future [1].

Designing and fabricating using biomaterials is generally addressed as “bio-based fabrication”, and sometimes misunderstood as bioengineering, bio-fabricating, or biomimicry, which refer, respectively, to altering microorganisms, designing living foundries, or looking to nature for formal and systemic inspiration for new objects [28]. In contrast, biomedical engineers who fabricate using biomaterials refer to the process as adding new functions and re-programming matter to achieve novel multi-functionality. The process is based on reverse engineering a natural structure to its material stock, so that a myriad of new forms can be given via dedicated fabrication methods [29]. In other words, it implies taking living matter, getting it to an inert state, and bringing it back “to life” as a workable material, while reformulating functions to achieve better performance, compensating for the non-living state of hydration, augmenting for sensing purposes, or even adding cells for the production of useful outputs. It involves reprocessing, engineering, and re-functionalizing, in infinite unexpected ways.

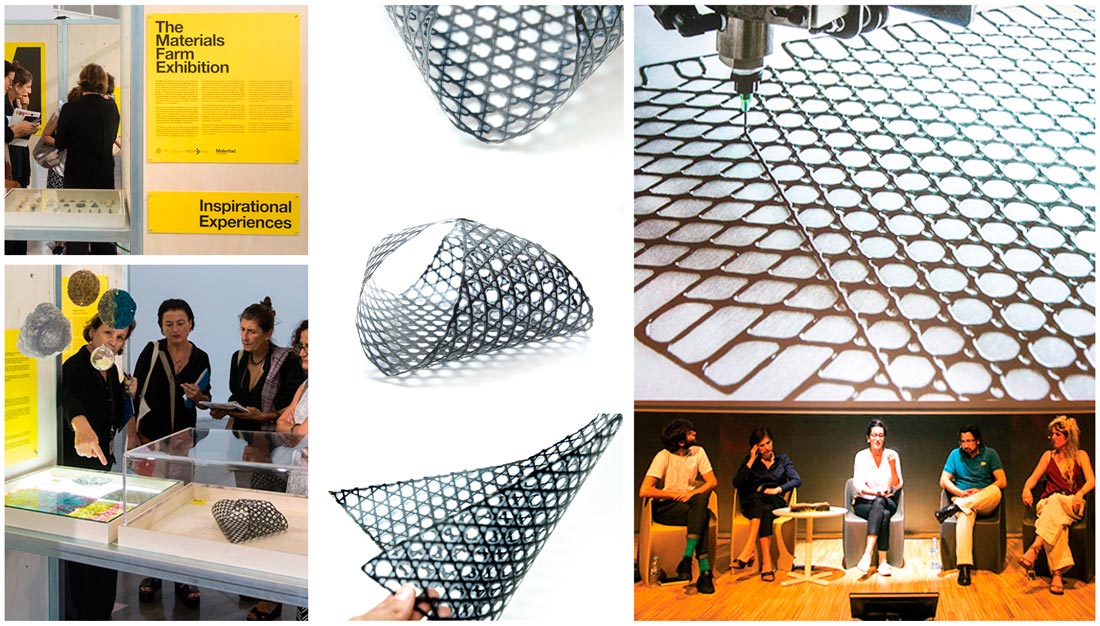

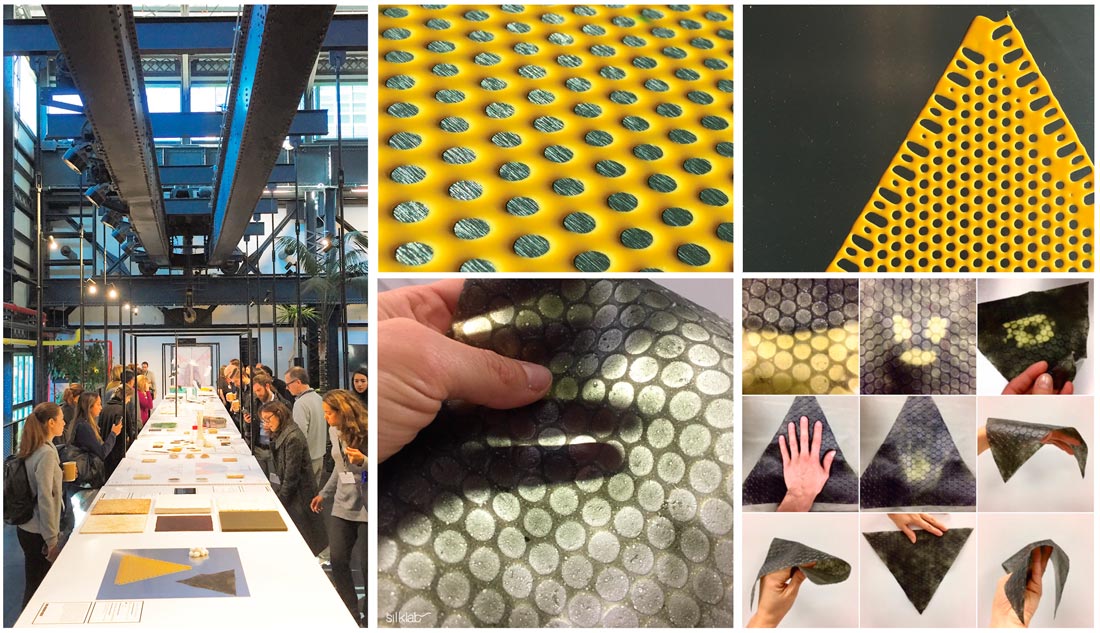

At the past “Materials Farm” exhibit at FADFest Barcelona 2017, a macro-lattice basket was 2.5D-printed out of colored silk fibroin and displays tunable flexibility for durable bending capabilities. It was developed using green chemistry and ensured ultimate biodegradation. Developed by architect Laia Mogas at the Living Materials Silklab, led by Dr. Fiorenzo Omenetto.

Augmented Form and Function

As discussed, biomaterials not only offer non-toxic manipulation, abundant availability, and mechanically adequate properties for product design but can also be employed as base building blocks to give infinite function to objects in a variety of design and fabrication platforms. Learning from Sullivan’s re-integration of form and function, and from the above-mentioned re-programming of materials using biomedical processing techniques, industrial digital design and fabrication can upscale biomaterials manipulation to invent new functions within material-driven forms. For instance, custom platforms developed at the Silklab (http://ase.tufts.edu/biomedical/unolab/home.html) combine structural design and environmental responsiveness via material-driven research to design with and towards new properties, such as optical gradation proportional to loading stress in mechanical parts, specific color response to molecule sensing in apparel, magnetism triggered by photons in flexible joints, thermal responsiveness to touch in furnishings, etc.

Augmented everyday products that heat up with light, change opacity in response to touch, show color with chemistry, or curl with steam can take the form of edible lattices or leather-like surfaces (as shown at the Biofabricate Summit at the New Lab NYC in 2017 – https://www.biofabricate.co), scarves (as shown at the Biotopia-Fest exhibit at the Munich Nymphenburg Palace – https://www.biotopia.net/en/event/skinclose2018), bracelets, eyeglasses, packages (presented at the FADFest Materials Farm Exhibit in 2017), purses (as will be shown at the Nature Design Triennial at the Copper Hewitt Smithsonian Design Museum in New York – https://www.cooperhewitt.org/events/current-exhibitions/upcoming-exhibitions/), T-shirts, tapestries (demonstrated by Lachesis, at the Design Does Exhibit, Barcelona Design Museum 2018 – https://vimeo.com/304908228), etc. The resulting biomaterial structures represent a viable approach to multifunctional material forms by design and an innovative exploration into future biocompatible objects and living spaces that can have a high impact in alleviating our planet’s resource and health issues.