Concrete has been used for millennia to construct houses and cities. The material has helped improve the lives of billions of people worldwide and is essential to continue to raise living standards in the developing world. Concrete, however, is also responsible for a significant part of global CO2 emissions, accelerating the current climate crisis.

Finding a solution to the enormous carbon footprint of concrete is therefore one of the main concerns in sustainable construction.

Much energy has been devoted in recent years to lower operational emissions, i.e. the carbon emitted from energy consumption during the use of a building. However, a large percentage of the emissions from buildings happen during the construction process. Embodied emissions – _or embodied carbon – _refers to the total amount of carbon emitted in the construction of a building. This includes the extraction and refinement of raw materials, transportation, and constructions practices, as well as the installation, maintenance and, finally, the disposal of buildings materials.

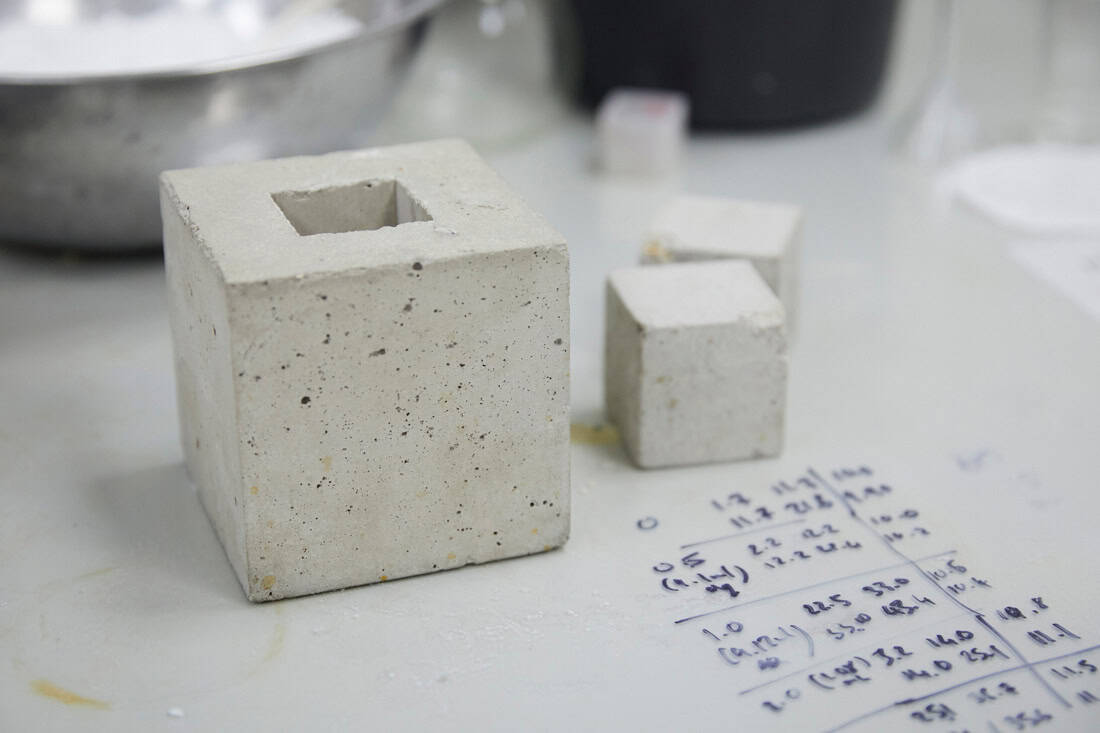

PhD students at Imperial College London, Sam Draper and Barney Shanks, have found a way to produce carbon-neutral concrete.

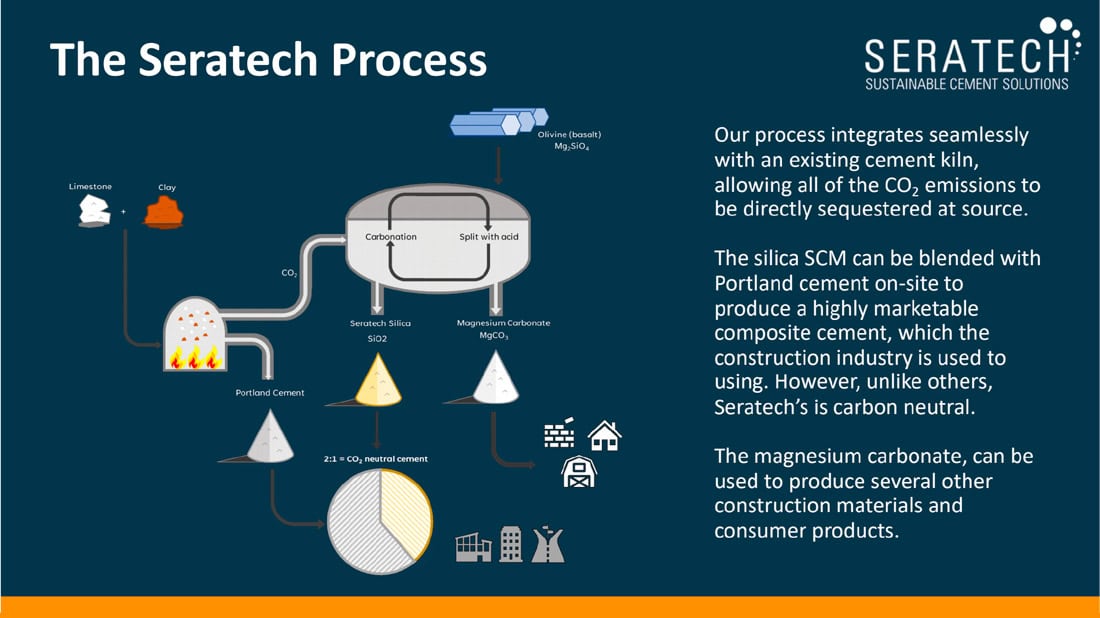

The team, which consists of material scientists and engineers, has developed an efficient, low-cost process to capture CO2 emissions directly from industrial flues. The process captures and stores all the CO2 through a chemical process, which also yields a cement additive – a silica – that can replace the amount of Portland cement in the concrete mix by up to 40%. The carbon capture associated with producing the silica means the concrete products can be zero carbon.

The raw materials used in Seratech’s process – waste CO2 and a magnesium silicate mineral – are naturally abundant all over the globe. Furthermore, the process integrates into existing manufacturing lines and the equipment used in concrete production. As such, it is possible to implement in every cement plant around the world and does not require major shifts in current practices or mindsets.

Given the huge carbon footprint of the construction industry, Seratech’s process has the potential to significantly reduce embodied emissions globally and to support future low-carbon construction.

Seratech is currently developing the design of a pilot plant to model the process at large scale.