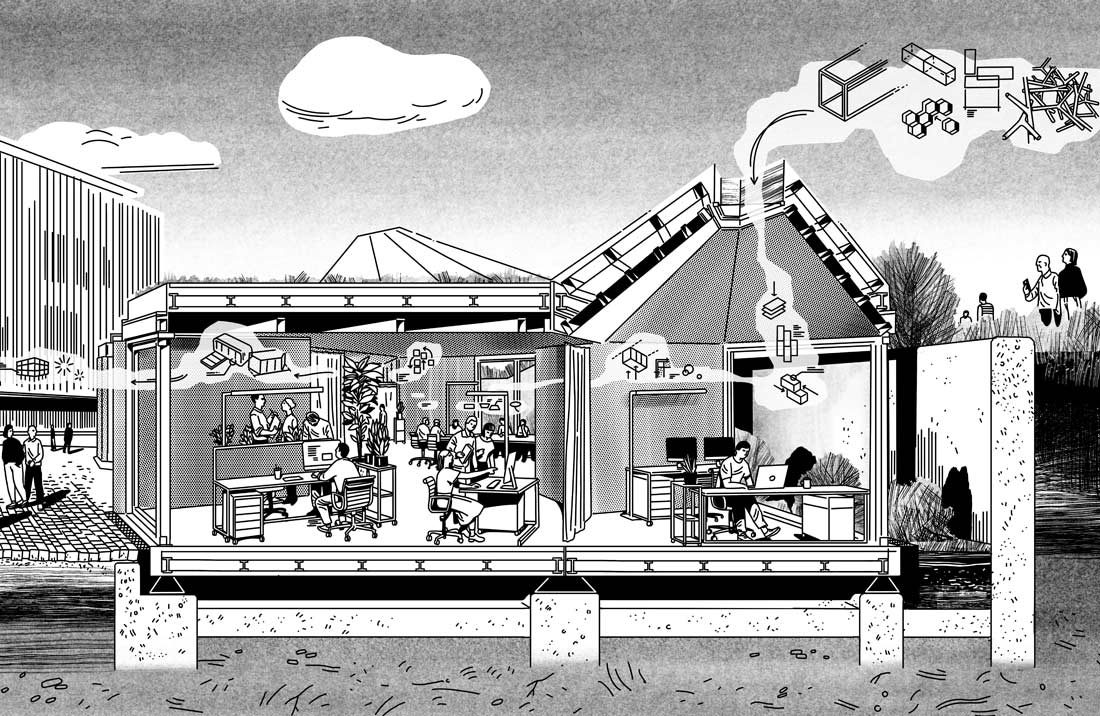

The partnership between CHK and KOMA began in 2014 by creating a master plan for the entrance and public area consisting of three modular buildings. The master plan demonstrates a strategic configuration design of the factory’s entrance, expanding on public space, in which each structure unveils modular versatility. Following the completion of the Modular Cafeteria in May 2014, CHK designed the Czech pavilion at EXPO 2015 in Milan, which was later converted into an office building for KOMA. The newly completed research center (2022) presents the third and final modular design, rooted in the concept of rotated containers functioning as columns, enabling a malleable architectural space to further expand on the notions of modular architecture.

Set to become an innovation hub for the factory complex to develop and explore new undiscovered building methods with modules, the research center forms an adaptable system that can meet multiple needs. Acting as an idea generator, the building is an important meeting place for all professionals to create innovative and special products, consequently becoming a default gathering point and evolution center for the future of modularity. Keeping in mind the structure’s principal function, the design highlights the vital element of transparency in the building. Creating a complex that is open and welcoming to the local community confidently reflects the principle of new concepts expected to take shape inside the rotated containers.

Created as a prototype for a new and adaptable modular system, the research center underlines the studio’s dedication to expanding the limitations of modular architecture and engaging in supporting local communities. Putting the focus on crafting new shapes that offer unrestrained modularity and showcasing an innovative system of multifunctional modular shapes, the studio is purposely shifting old paradigms and expanding on the typical rectangular construction to foster a transparent working environment.

Bypassing the restriction of the customary use of right-angled units placed side by side, the research center varies from a standard model in the basic re-imagination of the use of modular structures, making it a user-friendly model for the future of modular architecture.

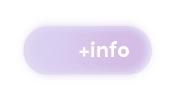

Containing three main module elements – the floor, the container, and the roof units – the composed space creates a new unique system. Spatial units containing the facilities are leveled onto the planar flooring modules, which are anchored to the foundation, functioning as columns. Placed in between the containers and the roof, vast window surfaces draw in an abundance of light, keeping the workplace open and connected to the exterior space.

The juxtaposition of the main modules and glass surfaces forms an all-inclusive spacious open area dedicated to horizontal and vertical working spaces. The area itself is entirely flexible, avoiding negative aspects of large open plan offices, and can be readjusted to meet the specific needs of any project, forming multiple adaptable and individual workstations. As a natural continuation of the modularity concept, the furniture design allows the office equipment to be supplemented, changed, and adapted to new needs over time: pieces of equipment can be customized simply by re-connecting the elements.

The building materials further aid in reflecting and understanding the innovative modular concept of the research center, with its perforated surface and visible details used to the maximum extent in their natural form. As a material that KOMA manufactures and uses daily, aluminum was a clear choice for the complex, aiding in the understanding of modular build principles.

CHK encourages further expansion and research on modular architecture and emphasizes its importance, “As the emerging trajectory for modular architecture and technologies continue to advance, we have positioned our capabilities in this area at the forefront of innovation to create promising solutions towards a future that we believe lies in modular architecture.”