The curriculum of Common Ground is rooted in ecological systems thinking. A public charter school, it serves 225 high schoolers, mostly from New Haven’s inner city. Its umbrella organization, the New Haven Ecology Project, engages over 12,000 children and adults from the surrounding metropolitan community in a range of farming and environmental research and restoration activities across the Common Ground campus throughout the year. A building committee comprising Common Ground faculty, administrators, and students commissioned our design team to collaborate with their school to develop a new art studio, science classrooms, and a community meeting and recreation room in a facility bordering the educational farm complex that lies beneath the ridge that forms New Haven’s West Rock Park.

As a basis for the design, they requested a functional, durable building that would support their broad range of activities while reducing long-term maintenance costs, and that would perform at the highest levels of energy efficiency in order to curtail greenhouse gas emissions over its service life. The greatest challenge to our team was that the new structure had to also serve as a pedagogical tool, legible in its use of physical resources and committed not just to the regenerative ecological function of its immediate site but also to the protection and promotion of the health of distant landscapes. Just as the school’s faculty and students sought to understand the potential downstream impacts of their daily farm and school activities – their use of water, the disturbance of soil with its associated hydrologic function, and the introduction of effluent waste – on the Mill River watershed and on the ecological health of Long Island Sound four miles to the south, they also hoped to acknowledge and explore the upstream impacts of their construction project.

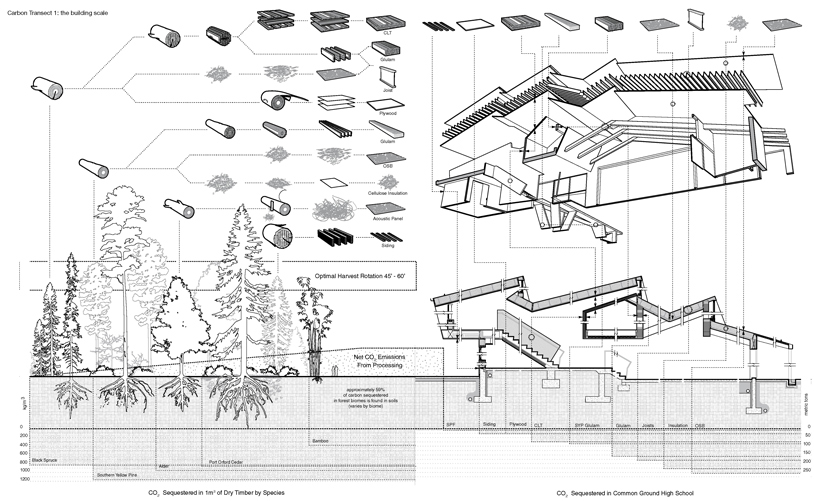

Like many modestly sized buildings in the United States, the arts and sciences building at Common Ground High School comprises an array of commercially distributed forms of structural biomass, in this case harvested wood products (manufactured from wood lamellae, fiber, flakes, pulp, and furnish) that has been industrially agglomerated (adhered and compressed through lamination or extrusion) into sheets, boards, batts, and structural shapes. Each plant based product has its own identifiable geographic source and an associated method and means of processing, from the input of energy and raw material to the generation of waste and emissions to soil, water, and air. In contrast to other classes of structural material – those that are extracted, sintered, and smelted from raw materials and industrial fuels drawn from deeper geological strata, where material formation cycles are measured on a geological timescale of tens of millions of years – structural biomass will regenerate within a relatively rapid time frame.

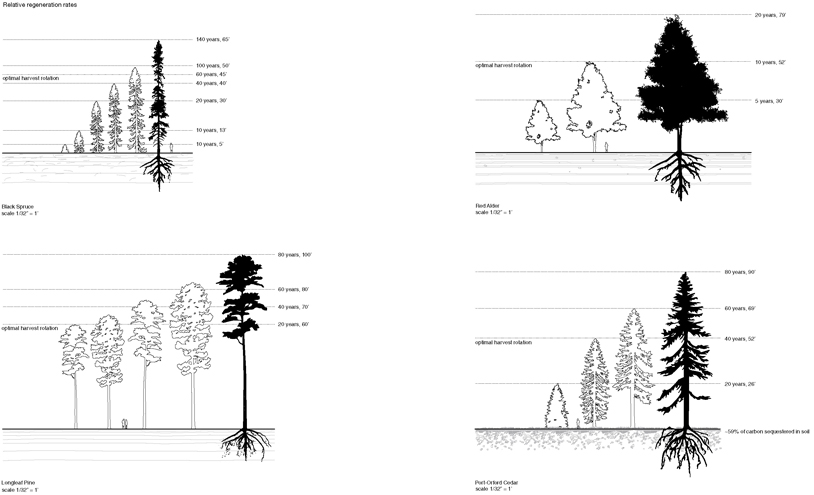

The regeneration rates within this “fast domain” of photosynthetic building material production and harvest, dependent on the species of plant, the climate zone and microclimatic context, and the degree to which forest soil media are disturbed during harvest, can be measured in decades. Although we must extrapolate to measure the quantity of atmospheric carbon not only taken up through that continuing photo-biochemical reaction in plant fiber but also accumulated in the soils and woody matter across forest landscapes, we can measure with great specificity the weight of carbon in wood of a particular species and moisture content. If we fairly account for the CO2 emissions discharged in the harvest, processing, and transport of the wood products and assemblies that we specify for our buildings, we can understand the net carbon sequestration potential of the built environment. We can optimize future cycles of sustainably managed forest sources. We can consider photosynthesis, with its relatively low energy density compared to that of fossil fuels, as a readily available, non-emitting form of manufacturing energy. And we can transform the constructed environment from an emissions source into a carbon sink.

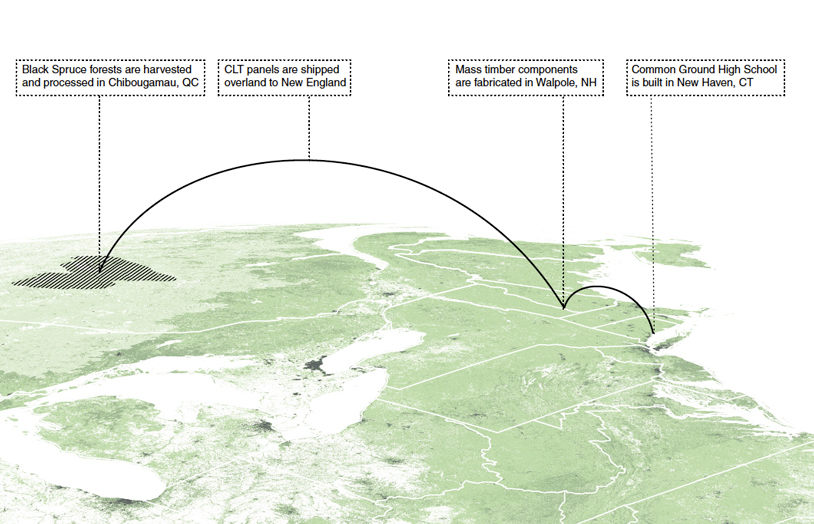

A critical decision in the design of the prefabricated system of wall and roof components that shape the new Common Ground High School building structure and envelope was to use glue-laminated (glulam) timber beams and cross-laminated timber (CLT) panels. The wood was harvested as part of a sixty-year rotation of patch clear-cutting and replanting within a five-million- acre area of black spruce forest in Quebec. It was processed into structural elements in a nearby production facility in Chibougamau, which were then shipped to a fabrication plant in Walpole, New Hampshire, where they were assembled into a structural system of insulated wall and roof components. Those components were trucked south, where they were installed as the shell and structure of the school building in New Haven.

A critical decision in the design of the prefabricated system of wall and roof components that shape the new Common Ground High School building structure and envelope was to use glue-laminated (glulam) timber beams and cross-laminated timber (CLT) panels. The wood was harvested as part of a sixty-year rotation of patch clear-cutting and replanting within a five-million- acre area of black spruce forest in Quebec. It was processed into structural elements in a nearby production facility in Chibougamau, which were then shipped to a fabrication plant in Walpole, New Hampshire, where they were assembled into a structural system of insulated wall and roof components. Those components were trucked south, where they were installed as the shell and structure of the school building in New Haven.

Three-ply black spruce CLT forms the tension surface in the cellulose-insulated, stressed skin panels that span the school’s classrooms and circulation spaces. CLT also forms the shear walls and the elevator and stair cores, which resist lateral wind and seismic loading, as well as the large open stairway at the center of the building. Black spruce glulam timber ridge trusses and roof rafters span the large multipurpose room that functions as a gymnasium, theater, and community meeting space. Visible in the public spaces, these mass timber elements and surfaces serve as reminder to the faculty and students who use the spaces of the regional forest landscapes 600 miles to the north that generated that material.

There are other species of wood represented throughout the building: laminated southern yellow pine planks, pressure treated for durability, form the primary path between the upper and lower campus, and strands, veneers, strips, and fibers from aspens, poplars, and longleaf pines comprise the engineered joists, studs, and panels that make up the hollow prefabricated wall and roof assemblies, which are densely packed with recycled cellulose pulp insulation. In addition to the usual array of hardwoods that serve as trim and cabinetry in a building of this type, wood strand-based acoustical panels line the walls of the classrooms and the roof of the multipurpose room to mitigate sound reflection, while compressed bamboo flooring lines the upper circulation spaces as a wearing surface. Of the various classes of construction material distributed throughout the arts and sciences building at Common Ground High School, 279 metric tonnes is structural biomass. This accounts for the removal from the atmosphere of 447 metric tonnes of CO2 – the equivalent of the annual emissions of 107 cars – now banked in the physical structure of the building for the duration of its lifetime. Furthermore, the forest stands that were its source are now beginning to regenerate, drawing new volumes of CO2 from the atmosphere.

The Impacts of Scale and the Benefits of Density

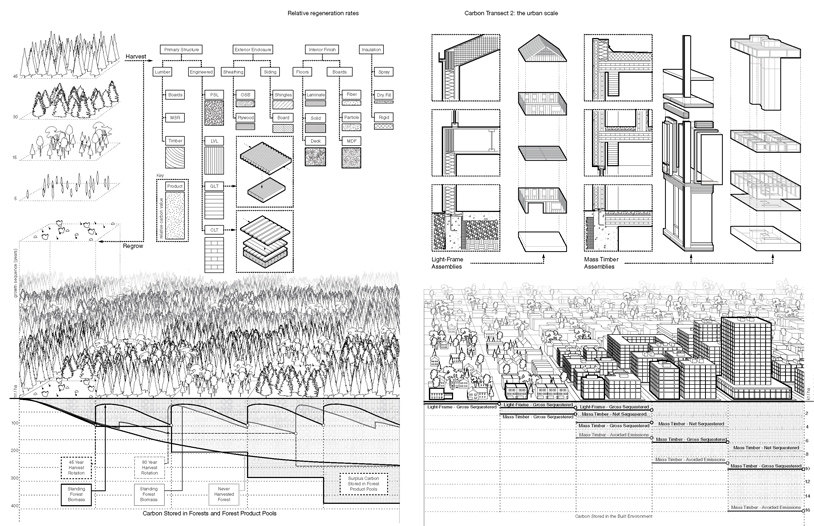

A transect inscribed in the building process to measure the economic exchange of carbon illustrates the latent impacts of our prodigious activities as builders. That the carbon stored in the structural material of a school building might offset the emissions embodied in the extraction and processing of that material, as well as some portion of a building’s operational impacts, seems compelling evidence of the ability of structural biomass to mitigate the significant carbon spike created at the beginning a building’s service life. These potential benefits offer both opportunities and challenges when considered at increasing scales of building production.

Some of the design challenges entailed in developing a biogenic building material supply chain and a broad-scale strategy of carbon sequestration through timber building may be obvious, but they are nonetheless worth restating here. First, to capture any real atmospheric benefit by drawing on potentially regenerative sources like forests, the industrial processes must remain carbon positive, that is the molecular carbon stored must outweigh, to the greatest extent possible, the CO2 emitted. Second, to reinforce those benefits, timber buildings must be designed and maintained to maximize their life span and to optimize their disassembly and the reuse of their material at that life’s end. Last, in order to ensure the viability of the planet as well as the sustainability of the biogenic supply chain, source forests and their harvests must be carefully managed. Forest regeneration must not be guided by a single attribute or objective. Neither the maximization of industrial material nor the re-absorption of atmospheric carbon should be the sole criteria for forest management. Instead, foresters should seek to replicate or, even better, allow the natural successive stages and cycles of forest regrowth that promote the full host of ecological services offered by healthy forests and other natural biomes and functioning ecological systems; these include soil stabilization and enrichment, biodiversity, hydrologic absorption, and solar energy absorption, among many others. Otherwise, we will simply reproduce the extractive mentalities and processes of mineral and fossil-based material supply systems – as well as past destructive logging practices. Instead we seek to minimize and, ultimately, replace such practices in their entirety.

A less evident but especially significant challenge relates not to how we build with biomass, but rather to what – or in what configurations – we choose to produce buildings from biogenic material sources. The new school building at Common Ground, though it serves a largely urban population, stands at the edge of an outer metropolitan ring of New Haven. The relatively dispersed landscape of low-rise buildings in diffuse formations, linked by extensive interwoven networks of transportation, energy, and utility supply, is the kind historically associated with population expansion. If we are to arrest landscape degradation by promoting forest growth and management as a sustainable source of industrial raw material, then we must simultaneously address the other ecologically deleterious driver of land alteration: suburbanization. Just as we seek to measure the carbon density of a given material or the CO2 absorption capacity of a forest stand or biome, we must also quantify the carbon impacts of changes in land use associated with projected regional and global demographic trends in urbanization. If we continue to deploy wood as we do today – as the primary material of low-density, low-rise suburban building morphologies that have been the historical commercial targets of the North American wood building industry – then the environmental gains we seek in the ecological management of forests and in the economic investment of forest carbon may never manifest themselves.

A corollary carbon benefit of building more densely with wood at the urban scale is that we will need materially denser, carbon richer structural assemblies to do so. The high-strength lamellar layups of wood in the glulam timber beams and CLT panels that span the larger spaces and bear the heavier vertical and lateral loads at Common Ground may make little economic sense when applied to single-family and two-family houses or small buildings with insignificant structural requirements. But when deployed to fulfill the structural demands of the kinds of larger buildings that aggregate to form dense cities, mass timber assemblies achieve not only meaningful economies of scale but also dramatic increases in our capacity to store a volume of carbon within a given land area.

Biogenic Material Supply Chains – A Timber City Protocol

In an ongoing interdisciplinary project that paralleled the design and construction of the Common Ground High School arts and sciences center, we are examining the potential biogenic synergies between cities and regional forests. In concept, our Timber City Research Initiative seeks to assess the potential ecological and economic linkages between the industrial production of construction biomass and the morphology of contemporary cities. More specifically, it seeks to quantify the relationship between the regenerative material supply and carbon absorption capacity of forests and the carbon sequestration capacity of wood urbanism. In its initial scope, we considered the enormous northeastern continental forests and the rapidly urbanizing landscapes that line the northeast seaboard of the United States.

As a means of accounting for the sustainable flow of carbon from forests into dense cityscapes, we first engineered a prototypical multistory mass timber building and calculated the net weight and associated carbon content of the biogenic material that would be sequestered in its primary structure. We then applied that timber building module to the development of a mid-rise (six to twelve stories) city district in New Haven, Connecticut. Using that hypothetical structural typology, which has been historically deployed to answer the building demands of northeastern post-industrial cities like New Haven, we quantified the material demands that the extraction of the needed timber would place on the source forests from which the trees would be harvested. With the help of the New England Forestry Foundation, we identified a 1,500-acre working forest in central Maine that could supply sufficient material to produce our structural module. We then applied to it a hypothetical land management plan, consisting of a forty-five-year rotational harvest of twenty-five-acre clear-cut patches, leaving 25 percent of the land area in contiguous reserves to maintain sufficient habitat for displaced species. Our team calculated the carbon contained in the original forest, the yield of structural biomass it could sustainably produce, and its capacity to absorb more atmospheric CO2 in its near half-century regeneration cycle We assumed that below- ground carbon pools would remain relatively stable through the use of sustainable harvesting procedures.

Though our analysis focused on the material transfer of carbon from the forest biome to the constructed landscape of cities, we also considered the industrial emissions associated with the extraction, processing, and transport of harvested wood products, including the incineration of wood waste for industrial energy. While these embodied CO2 emissions had the expected effect of reducing the net quantity of carbon that our structural prototype and its urban deployment scenario could claim to accrue, the carbon sequestration potential of wood urbanism proved significant. This was especially the case when we considered the industrial emissions avoided with the substitution of mass timber for the various mineral-based structural materials that currently dominate the construction of multistory urban buildings. Compared to the building at Common Ground High School, which sequestered the equivalent carbon emissions of 107 vehicles within the building’s biomass assemblies, a single seven-story mass timber building occupying the same footprint is capable of offsetting the annual emissions of 563 vehicles.

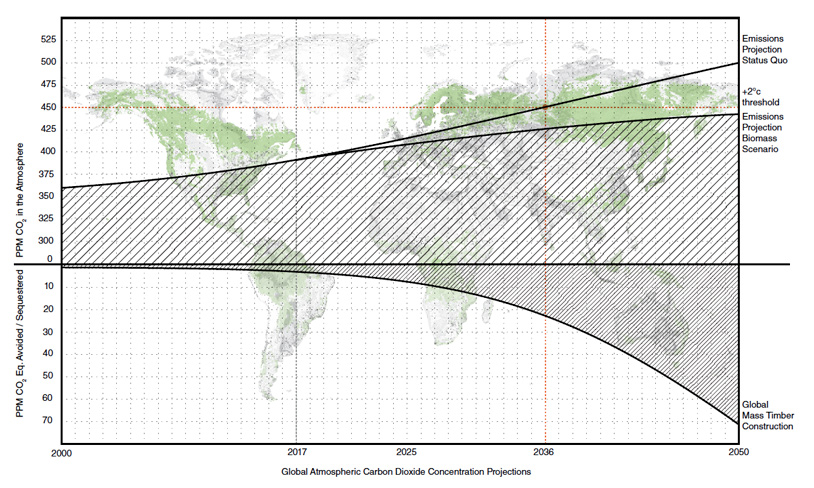

A Global Biomass Scenario

Through the unfolding stages of the conception, planning, and construction of the center at Common Ground High School, we returned repeatedly to its “carbon transect” as both concept and illustration. The idea of the building “lifecycle,” another more familiar term used to describe the impacts of building production and operation, has the benefit of carrying with it a set of codified assessment tools and methodologies. But in establishing the valuable analytical system boundaries of a building’s lifecycle, we suggest that a kind of generational renewal also occurs. It is easy to overlook a longitudinal concern in production of the built environment – the way in which those successive generations of non-timber buildings accrue and amass debt in the form of concentrated atmospheric CO2. Given the frightful upward trajectory of those emissions and its implications in the face of rising demand for global construction, we sought a means for Common Ground teachers to illustrate and help students visualize this ever-accumulating burden that they had inherited, the way in which our current building practices contribute to it, and responsible strategies for them to possibly begin to reduce it.

As a model of material and structural design, environmental assessment, and land use and planning policy, a global Timber City scenario offers a sustainable means to meet the anticipated building demand of a rapidly urbanizing global population. Rather than exploiting already depleted material resources, it seeks – in both the inherent spatial, material, and infrastructural efficiencies of dense urban building morphologies and the unique carbon storage capacity of structural timber assemblies – to reduce the footprint, measured in land area and CO2 emissions, of the multifold expansion of global cities in coming decades. A sustainably managed forest supply commercially linked to urban construction demand increases the economic value of wood fiber while incentivizing the protection and potential expansion of global forests for both their carbon sequestration and monetary value. It posits photosynthesis as a valuable form of global manufacturing energy, as opposed to the more concentrated but environmentally deleterious forms of energy – primarily fossil hydrocarbons – that fuel the manufacture of other greenhouse gas emissions-intensive classes of structural material. It offers the construction of new and revitalized timber cityscapes as a critical tool in the global effort to mitigate climate change by turning dense urban settlement into a continuous carbon sink, functioning at the scale and capacity of the forests that are its renewable source.