From architects going beyond blueprints to explore buildings in virtual reality, to the rise of the design-build studio, to the emergence of advanced digital software and production techniques, the influence of digital on the field of architecture seems to grow larger every day.

But as welcome as digital empowerment is, does it come at a cost? For many, the adoption of digital tools — especially in the design-build movement — has fuelled fears about the demise of traditional architectural techniques and a depreciation of interest in its classical virtues. A plywood building made with a CNC machine still looks — and feels — digitally fabricated.

Digital artisans

Instead of accelerating the demise of traditional craftsmanship, what if digital tools enhanced it and expanded the possibilities of what we can make? What if an architect could use a digital tool — a CNC machine, say — to create something with a distinctly human quality? How might the machine be applied to skills such as woodwork and metalwork? Could it be used to make objects with the aesthetic appeal, including the touch and feel, of a handmade object? Could it also make objects that can be scaled — objects with applicability to architecture?

These were the timely questions that three architects recently explored as residents at SPACE10 — IKEA’S external future-living lab. With a shared interest in exploring how digital tools can be applied to traditional techniques — and the potential of a CNC milling machine in particular – Yuan Chieh Yang, Benas Burdulis, and Emil Froege together found answers in three very different but eye-opening ways.

Rethinking construction with Japanese joinery

Yuan Chieh Yang showed how a CNC machine could be used to reproduce a one-thousand-year-old style of Japanese joinery. The machine allowed him to make a 10-metre-long pole using wooden pieces joined together by hands, without any screws or hand tools. In particular, the machine allowed him to create subtle curves in the wood, which meant the individual pieces could be easily and securely locked together — and, if needs be, disassembled. Because this old-meets-new technique involves laminated pieces, meaning it can use recycled wood, it is scalable and therefore suitable for use in construction.

Creating patterns that enhance our perception of light

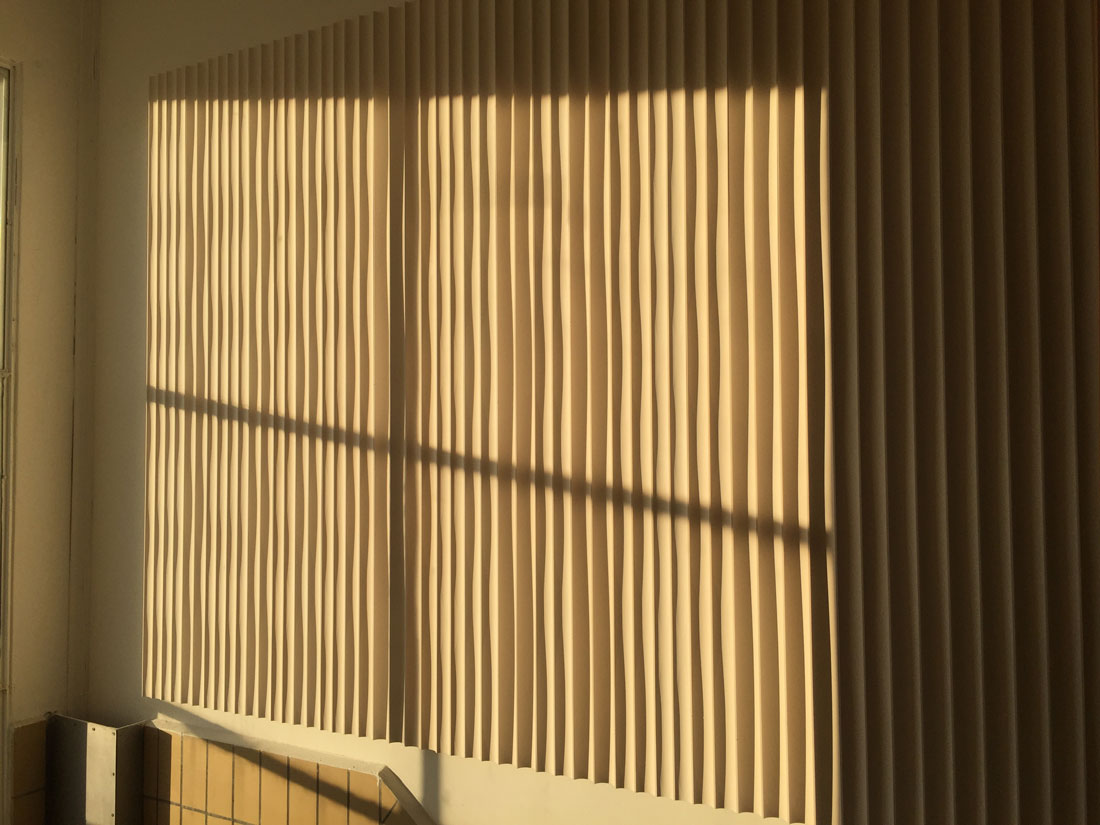

Benas Burdulis used the precision of the CNC machine to create a patterned wall which highlights and amplifies daylight entering an interior space. “The most effective element is the varying curve that runs through each groove,” he says about the subtle fluted effect that he made using the CNC machine.

“When hit with direct light, it creates a subtle wave of shadow that emphasises the fluid nature of the light. It’s something you might not notice at first, but when you do, it will make you pay more attention to it and notice the light in the space more strongly. The goal is to make people more aware of their own perception and sensing of space.”

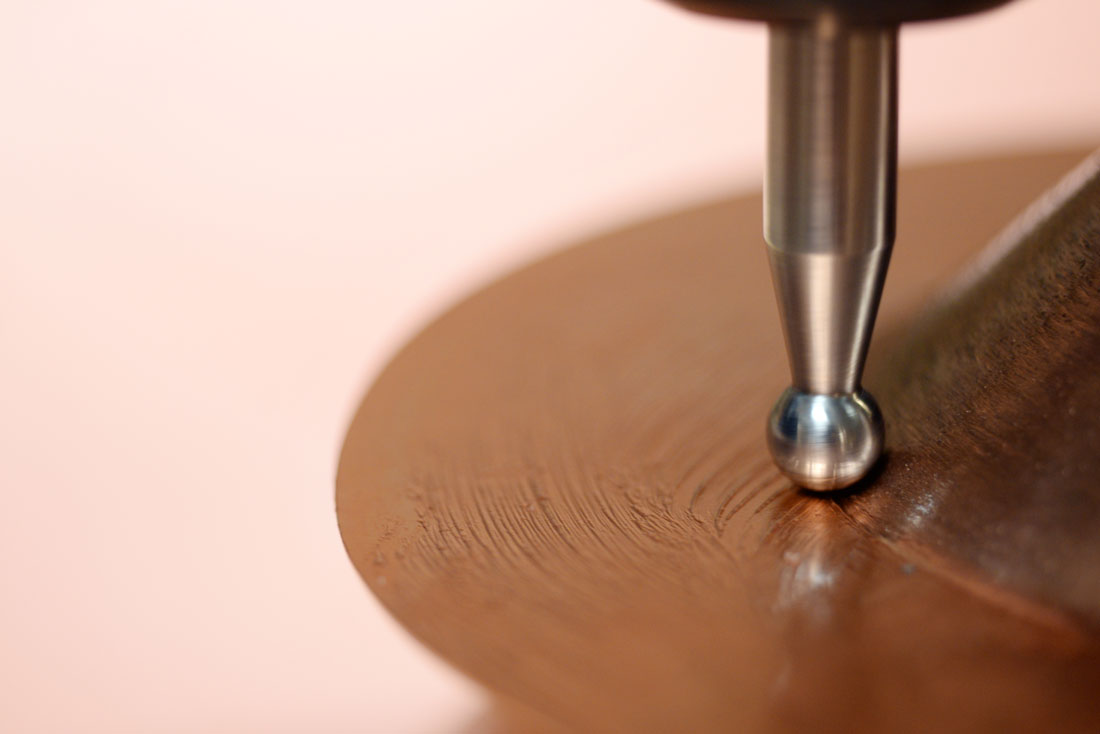

Shaping copper by machine – as if by hand

Emil Froege saw the CNC machine as a way to “understand the relationship between the digital and the natural”. He explored the possibilities of using it to shape copper — a material that people have been shaping by hand for centuries — in order to make a light reflector. First, he used the CNC machine to cut out a shape from a copper sheet. He then used it to machine out a mould and followed the same tool path to force the copper against the mould. “You get the trace of the tool and you see this continuous spiral line throughout the entire object which is quite mesmerising,” Emil says. Finally, to see if a CNC machine could do what has long been done by hand — shape metal — he replaced its cutting tool with a small metal ball. It could.

Our installation is reached through these continuously refined details. They become deeper than something ornamental and aesthetics in general. The copper reflector became something poetic, like being met by the shadow of a candle in the evening.

Emil Roman Froege

Classical techniques and 21st century tools

The three objects remain on permanent display at SPACE10 in Copenhagen — a testament to our growing ability to combine classical craftsmanship with 21st century tools, and digital ones in particular, in order to produce objects that look and feel as if made by humans. They also exemplify how digital fabrication isn’t necessarily something to be feared, but instead should be welcomed both by architects and anyone who cares about the spaces in which we live.